MAJA

Contact: Mr. Li

Mobile: 13817371428

Landline: 021-69896133

Website: ytrans.cn

Address: Qingpu District, Shanghai Green Pine Road 3562

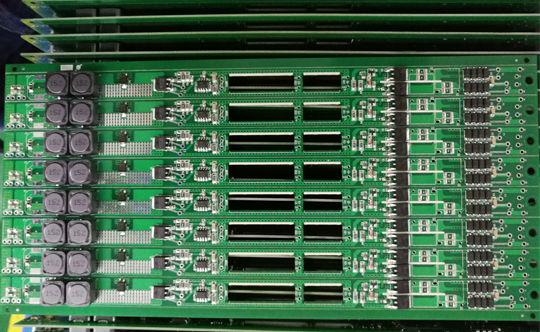

There are many factors that affect the product quality in the process of electronic product patch processing. For example, we often know that the chip processing equipment, technology, technology and PCB design, as well as the choice of chip processing materials have a great impact on product quality . Select the appropriate substrate material can effectively improve product performance, ensure product quality. So chip processing patch materials which? Chip processing patch materials are mainly two types, one is based on the metal-based patch of organic material; second is the ceramic chip and porcelain package Copper-clad patch as the representative of the inorganic patch materials.

1, metal patch: the use of 0.3mm-2.Omm thick metal plate, such as aluminum, steel, copper and epoxy prepreg and copper foil three composite heat pressed. Metal plate to achieve large-scale chip processing, and has the following performance characteristics:

(1) good mechanical properties: metal-based patch with high mechanical strength and toughness, better than the rigid material patch can be used for large-scale chip processing, and can undertake overweight components installation, in addition, the metal-based The patch also has high dimensional stability and flatness.

(2) good thermal performance: As the metal patch directly in contact with the prepreg, it has excellent thermal performance. Shanghai patch manufacturers use metal patch for chip processing, metal patch processing can play a cooling effect, the cooling capacity depends on the material and thickness of the metal patch and the thickness of the resin layer. Of course, taking into account the thermal performance, but also should take into account the electrical properties, such as the dielectric strength.

(3) Electromagnetic shielding can be shielded: In high-frequency electronic circuits, electromagnetic radiation to prevent the radiation has always been a designer's concern, the use of metal-based patch can act as a shielding plate, play the role of shielding electromagnetic transition.

2, electronic ceramic materials: electronic ceramic function is one of the basic materials of microelectronic devices, has the following advantages:

(1) New packaging materials for large-scale integrated circuits and new high-performance insulating ceramics for high-frequency insulation;

(2) Dielectric ceramics and ferroelectric ceramics for new microwave ceramics and ceramic capacitors which can be substituted for import;

(3) large-scale integrated circuits with high-performance chip components for electronic ceramic materials and products.

On the chip processing patch materials which are introduced today. Patch processing patch material has many types, each with advantages, according to the actual use of processing conditions, select the appropriate patch material, in order to ensure the final product forming quality.

Phone:+86 21-69896133 A company site: Qingpu District, Shanghai Green Pine Road 3562

Two companies: Anting Town, Shanghai Caoan Road 4514, Lane on the 3rd